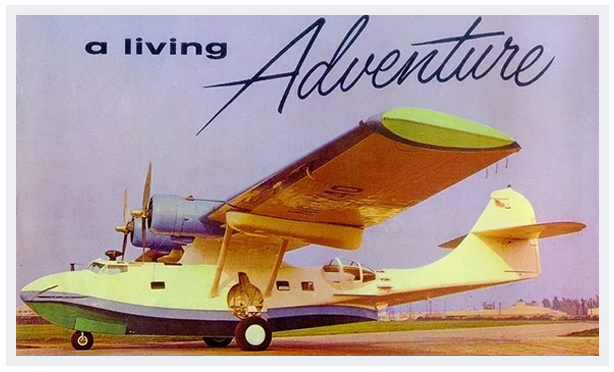

WW2 Military Seaplane Project for Sale

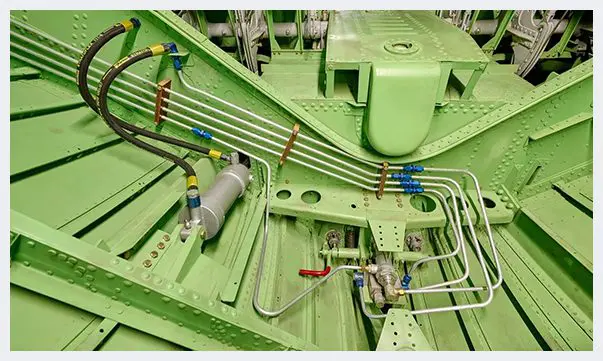

We invite you to an extraordinary opportunity in aviation history. We're offering a WW2 military Seaplane, a cherished relic of the past, which stands as a testament to the heroic tales of its era. While it's currently in the restoration phase and not yet flight-ready, the bulk of the meticulous restoration work has been accomplished, making it an exceptional canvas for your aviation dreams.

A Project of Legacy and Adventure

This unique aircraft isn't just a piece of history; it's a gateway to adventure. For aviation enthusiasts or collectors passionate about military aircraft, this project presents an unmatched canvas for completion. The hard work of restoration has been diligently undertaken, setting the stage for its transformation into a glorious airborne masterpiece.

The Ultimate 'Magic Carpet'

Imagine taking this Amazing historic aircraft to the skies, showcasing it at air shows, or embarking on thrilling adventures across the globe. We envision this aircraft as the ultimate 'magic carpet,' offering an opportunity to explore the world in a way that few experiences can match. For more information, visit our About page.